What Is Photovoltaic Ribbon?

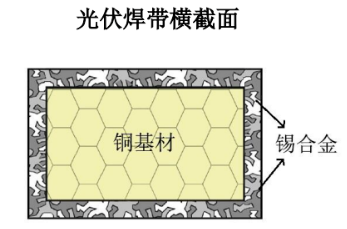

Photovoltaic Ribbon, also known as tinned copper wire or tin-coated copper ribbon, is an important component of photovoltaic modules and is used for connection in photovoltaic cell packaging. The raw materials of Solar photovoltaic Ribbon products are mainly copper and tin alloys, which are composed of substrates and surface coatings.(In the picture below you can see that the photovoltaic ribbon is mainly composed of two parts, they are copper wire and tin alloy).In this video, you will clearly understand how PV RIBBON is produced.

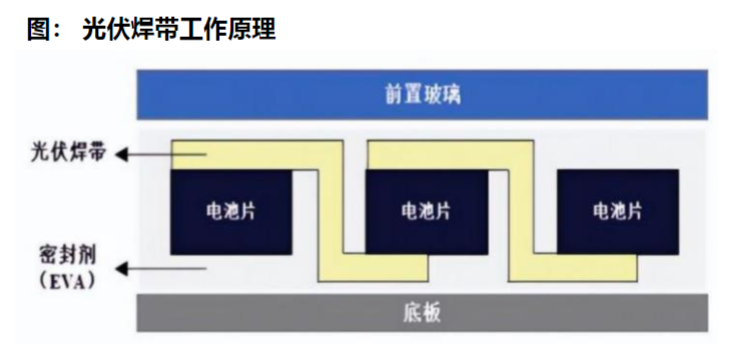

The Solar photovoltaic Ribbon will lead out the electric energy converted from light energy on the silicon wafer and transmit it to the electrical equipment, playing an important role in conducting electricity to increase the output voltage and power of photovoltaic modules.(In the following pictures, you can learn how photovoltaic welding ribbon works.)

Solar photovoltaic Ribbon can be divided into interconnection welding PV ribbons and busbar welding ribbons according to the product application direction:

The interconnection photovoltaic Ribbon is a tin-coated photovoltaic Ribbon used to connect photovoltaic cells and collect and transmit the current of photovoltaic cells; the interconnection welding tape mainly includes conventional interconnection welding tape, MBB welding tape, low-temperature welding tape, low-resistance photovoltaic Ribbon, etc.(the below images are for interconnection welding PV ribbons and busbar welding ribbons,you can clearly understand what are the PV ribbons)

The busbar photovoltaic Ribbon is a tin-coated welding tape used to connect photovoltaic cell strings and junction boxes and transmit the current of photovoltaic cell strings. It connects many cell strings to achieve a complete current path. The busbar welding tape mainly includes conventional busbar photovoltaic Ribbon, punching photovoltaic Ribbon, black welding tape, bent photovoltaic Ribbon, etc.

What is the offset of the solar photovoltaic Ribbon of photovoltaic cells?

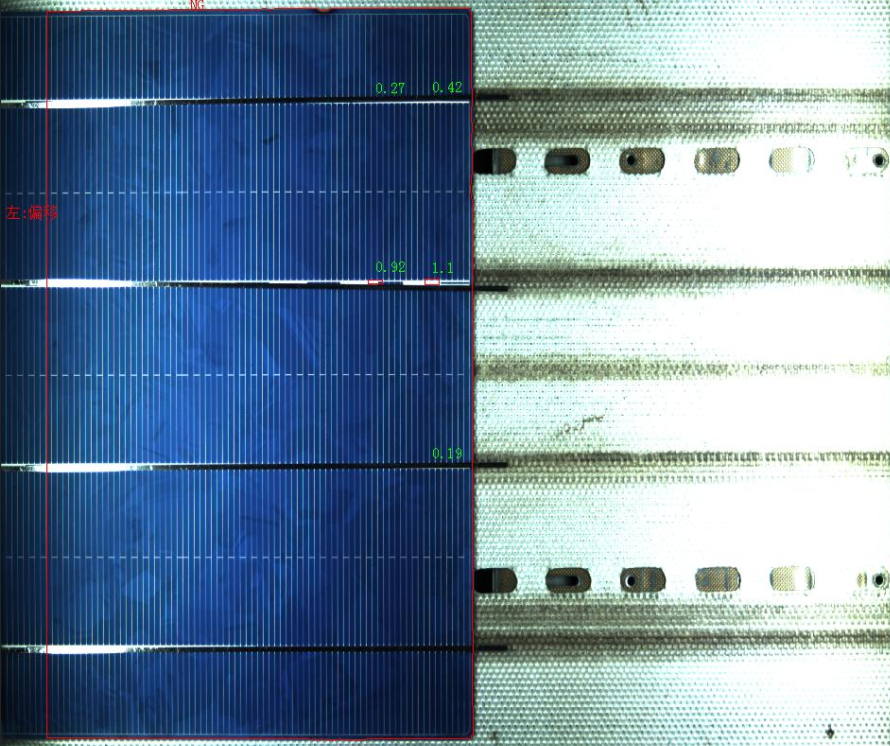

The offset of the PV welding strip or PV IBBONS of photovoltaic cells will affect the normal passage of current and cause the power attenuation of the components. In the production process of photovoltaic panels, due to uncontrollable factors such as welding process fluctuations and oxidation of welding rods, various defects will occur in photovoltaic panels, and the offset of photovoltaic Ribbon is one of them.(The below image is for the offset of the solar photovoltaic Ribbon of photovoltaic cells)

The offset of photovoltaic Ribbon will affect the normal passage of current and cause the power attenuation of components. The welding strip detection of existing photovoltaic panels is mainly completed by manual sampling during the production process.

Therefore, in normal operations, operators should keep in mind that interconnection strips with abnormal welding strip deformation cannot be used, and must straighten the welding strip before starting welding to ensure that the welding strip is straight and completely covers the welding printed line of the cell to avoid white exposure.

What is the cold welding of photovoltaic cells?

Cold welding of photovoltaic cells is that the welding strip on the cell fails to be welded to the main grid line of the cell, resulting in a small cell unit unable to contact and conduct electricity, thus forming a short circuit.

It is not easy to observe the phenomenon of cold soldering when the battery string is viewed directly. It is easier to observe the abnormality of cold soldering of the battery cell with a slight angle deviation.

When the battery cell is detected by EL equipment, a dark area symmetrically along the main grid direction appears, which is a cold soldering phenomenon.

When the battery cell is welded, factors such as too low welding temperature, insufficient heating time, insufficient flux concentration, pin shedding, ejector stuck, too thin tin layer of solder strip, and mismatch of silver paste of the battery cell may cause cold soldering.

What is over-soldering of photovoltaic cells?

Over-soldering of photovoltaic cells is a phenomenon in which the tin on the solder strip melts and forms a tin-silver alloy with the main grid silver paste, resulting in excessive resistance in the area.

When the battery cell is over-soldered, you can see that the silver paste is black, or the crystallization is serious. If there is a tin mark on the solder pad, but the solder strip is not in reliable contact with the battery cell, this indicates that the tin layer on the solder strip has melted. EL detection shows that the illuminated area is rectangular and connected to the main grid line, which is an over-soldering phenomenon.

The main reasons for over-soldering of battery cells are too high temperature, too long heating time and short cooling time during welding.If the welding head position is too low or the temperature of the welding station is set too high, it will also cause over-soldering of the battery cell.

What Photovoltaic Ribbon Equipment Can We Manufacture?

Photovoltaic Busbar Production Line

MBB Double Wire PV Ribbon Machine

PV Ribbon Machine With Tin Coating Lines

Copper PV Ribbon Machines

Photovoltaic Bus Bar Rolling Machine With Tin Coating Lines

PV Ribbon Machine With Tin Coating Lines

Copper Wire And Photovoltaic Ribbon Machine